Why Quality Matters for Printing Equipment

In today’s environmentally conscious market, businesses often weigh the options between recycling and remanufacturing when it comes to office equipment like printers. While both contribute to sustainability, they yield very different outcomes in terms of quality and durability. Understanding these distinctions is essential for companies that rely on high-performance equipment.

Recycled printers typically go through a process where materials are recovered, or minor repairs are made before resale. This reduces waste but can result in varied performance, limited lifespan, and more frequent replacements, depending on the device’s condition before recycling.

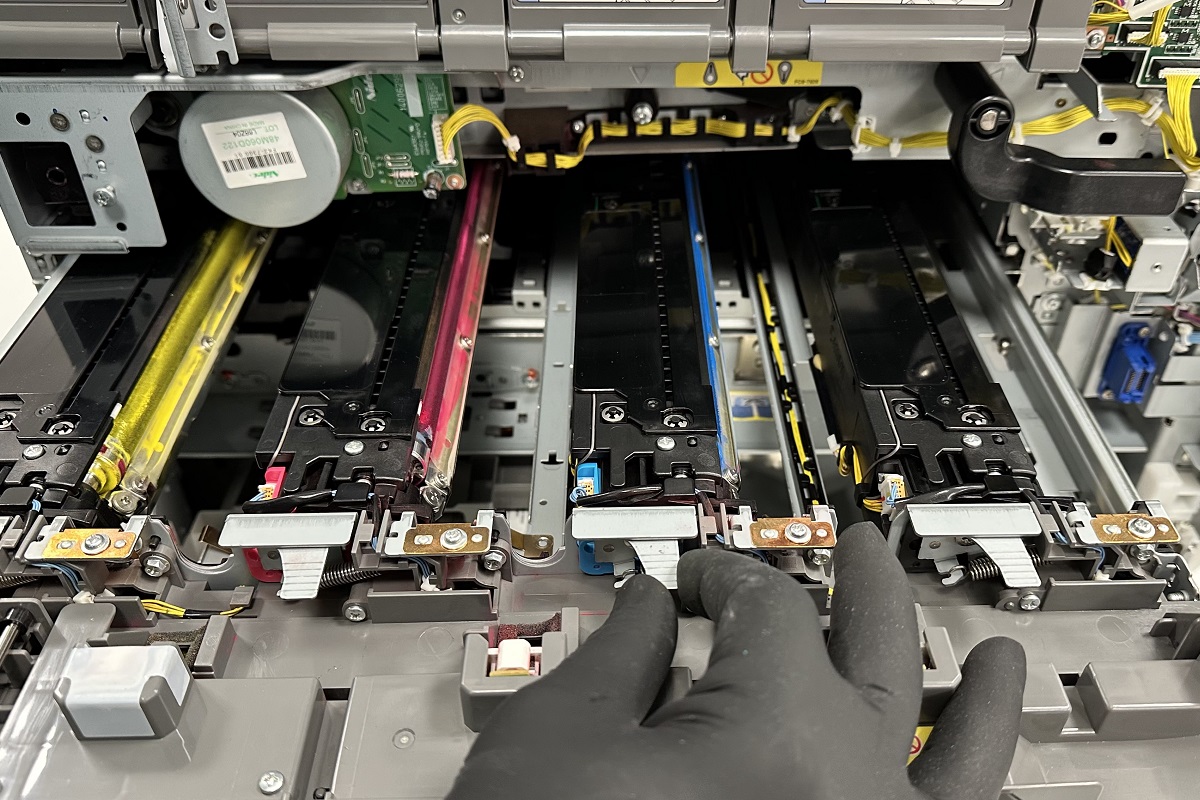

Remanufactured printers, however, follow a far more rigorous process. Each device is disassembled, thoroughly cleaned, and any worn or defective parts are replaced with premium components. The process concludes with stringent testing to ensure the printer meets OEM standards—or even exceeds them in some cases.

Remanufactured printers also come with warranties supported by international certifications, giving companies confidence in a reliable, long-lasting investment. In a market where businesses demand quality and dependability, remanufactured printers provide a perfect blend of sustainability and performance.